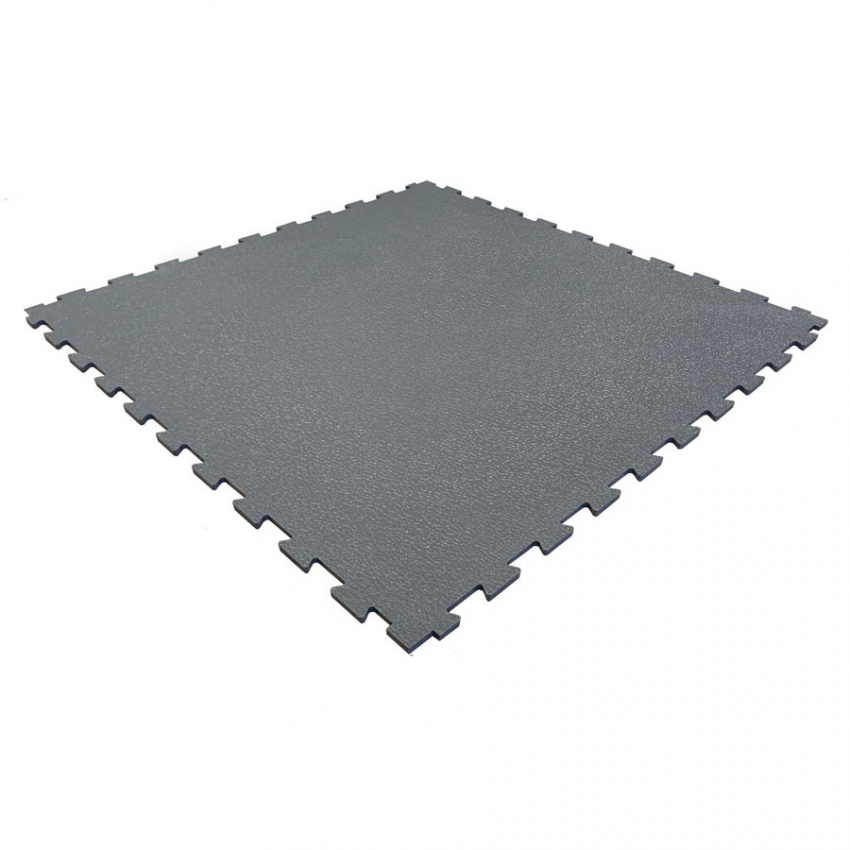

AS / ESD PVC warehouse tiles

Antistatic and Conductive range:

The TRAFICFLOOR AS ESD tile enables operators to handle static-sensitive components in complete safety, eliminating the risks associated with the presence of static electricity: dust fixation, physiological discomfort, damage to electronic components, risk of explosion, etc.

TRAFICFLOOR AS ESD is ergonomic and non-slip for user comfort and safety. It keeps the floor flexible to prevent breakage of fragile components. Its removable and reassemblable fixing system is ideal for workstation transfers.

Available in 50 x 50 cm tiles (4 tiles/m²).

Traficfloor AS :

- Transverse resistance: 1.6 .109 Ω

- Color: available in Gris Bleu Ral 7031

Traficfloor ESD :

- Transverse resistance: Rx (Ω) < 104Ω

- Requires installation of an earthed copper adhesive. Measurements are taken at five points on the slab, 25 cm apart, first at 10 V if the result is <104 Ω, then at 100 V if not, as specified in the standard. Then take the geometric mean of the values obtained.

- Colors: available in Black Ral 9017 and Grey Ral 7046

RECOMMENDED APPLICATIONS :

AS/ESD PVC tiles are particularly suited to the electrical, electronics, electromechanical and IT industries.

- Workshops equipped with numerically controlled equipment

- EPA (Electro Protected Area) zones in the automotive and electronics industries, etc.

- Computer control units

- Telephone centers

Also ideal for all industrial production areas at risk from static electricity: automotive, aeronautics, etc.

Indoor use : not recommended for outdoor use (please contact us and refer to the instructions for use).

| TRAFICFLOOR AS ESD |

Data sheet

| Format | Slabs |

| Surface | |

| Properties | ESD / AS Fire resistant Non-slip |

| Thickness | |

| Weight | |

| Fire classification | |

| Certifications |

- musculoskeletal disorders (MSD),

- electrical shocks ,

- ensure a clean and healthy environment in the food industry, by preventing the proliferation of bacteria for example.

- Anti-fatigue mats : can be used in manufacturing industries, packaging centers, retail outlets and catering establishments.

- Antistatic mats: used in industries (welding stations).

- Agri-food mats: used in industrial kitchens, restaurants/hotels, canteens, etc.

- Wet environment: in a wet environment, the mat must not be slippery, so it must have anti-slip properties and a perforated surface to allow drainage of liquids.

- Dry environment: in a dry environment, the mat must have a granular, ergonomic bubble, striated or diamond plate surface. However, depending on the environment in which the mat is used, it must meet specific hygiene standards (kitchens, pharmaceutical industries, food processing plants, etc.).

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.