Non-slip rubber mat

Dry and/or damp environments - Moderate use

This rubber mat with grooved surface has a wide range of uses. It has good anti-slip and anti-fatigue properties, and is suitable for moderate use. It is particularly resistant to shocks and slipping. It is recommended for use in industry and in medium-traffic, trampled areas. Its resistance to temperature variations makes it suitable for both indoor and outdoor use.

Available in rolls and made-to-measure.

RECOMMENDED APPLICATIONS :

This mat can be used in sheltered outdoor areas. It is also recommended for use in industry (in front of machines, unloading docks, medium-traffic areas).

Examples of use: construction sites, utility vehicles, workbenches, unloading docks, animal walkways, van ramps, etc.

| BTB caoutchouc cannelé |

Data sheet

| Format | Roller |

| Properties | Anti-fatigue |

| Composition | |

| Thickness | 6 mm |

| Weight | |

| Fire classification | Dfl-s2 |

| Resistant to chemicals | No |

| Environment | Dry environments Wetlands |

| Operating temperature | |

| Intensity of use | Slight |

| Hardness | |

| Wear index | 1/3 (Good) |

- attractive design

- resistance to traffic

- excellent functionality

- Humid environment: you should opt for an absorbent or non-slip anti-fouling mat to prevent moisture from penetrating your premises.

- Dry environment: you should opt for a scraping mat that will catch all the debris and dust found under the soles of your customers' shoes.

- Up to 250 passages/day: standard traffic mats .

- Up to 500 passages/day: heavy traffic mats.

- Over 500 passages/day: very heavy traffic mats.

- Scraping mats : Scraper mats have dry, hard fibers for effective scraping of shoe soles. Used in dry, dusty environments.

- Absorbent mats: Absorbent mats absorb moisture brought in by passers-by. Depending on the mat, they can absorb 3 to 6 L of water per m2, and are known as water-barrier mats.

- Non-slip mats: Anti-slip mats also have a scraping function, preventing dirt from entering the premises. However, they have one more function than scraping mats: they have anti-slip properties. These mats are most often used outdoors.

- Public buildings

- Condominiums

- Offices

- Administrations

- Stores

- Schools

- etc ...

- Colors to suit all tastes

- Designs to enhance your entrance

- Sizes to fit your space.

- musculoskeletal disorders (MSD),

- electrical shocks ,

- ensure a clean and healthy environment in the food industry, by preventing the proliferation of bacteria for example.

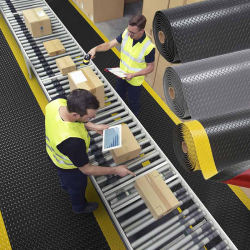

- Anti-fatigue mats : can be used in manufacturing industries, packaging centers, retail outlets and catering establishments.

- Antistatic mats: used in industries (welding stations).

- Agri-food mats: used in industrial kitchens, restaurants/hotels, canteens, etc.

- Wet environment: in a wet environment, the mat must not be slippery, so it must have anti-slip properties and a perforated surface to allow drainage of liquids.

- Dry environment: in a dry environment, the mat must have a granular, ergonomic bubble, striated or diamond plate surface. However, depending on the environment in which the mat is used, it must meet specific hygiene standards (kitchens, pharmaceutical industries, food processing plants, etc.).

Anti-dirt-repellent mats are the first line of defense in keeping dirt and debris out of buildings. They improve air quality, reduce noise resonance, extend floor life and cut maintenance costs.

Dirt-repellent mats also facilitate access for people with reduced mobility, while ensuring the safety of all users (avoiding falls, slips, etc.). But they also contribute to the cleanliness and hygiene of your premises, while enhancing your image, since the entrance is the first impression your customers will have of your establishment.

To cut a long story short, a dirt-repellent mat must meet 3 main criteria:

When choosing an antisoiling mat, there are a few criteria to consider:

Your environment:

Type of traffic :

There are 3 ranges of dirt-repellent mats:

Professional dirt-repellent mats are used in all establishments with one or more entrances, such as :

We offer a wide choice of dirt-repellent mats:

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.