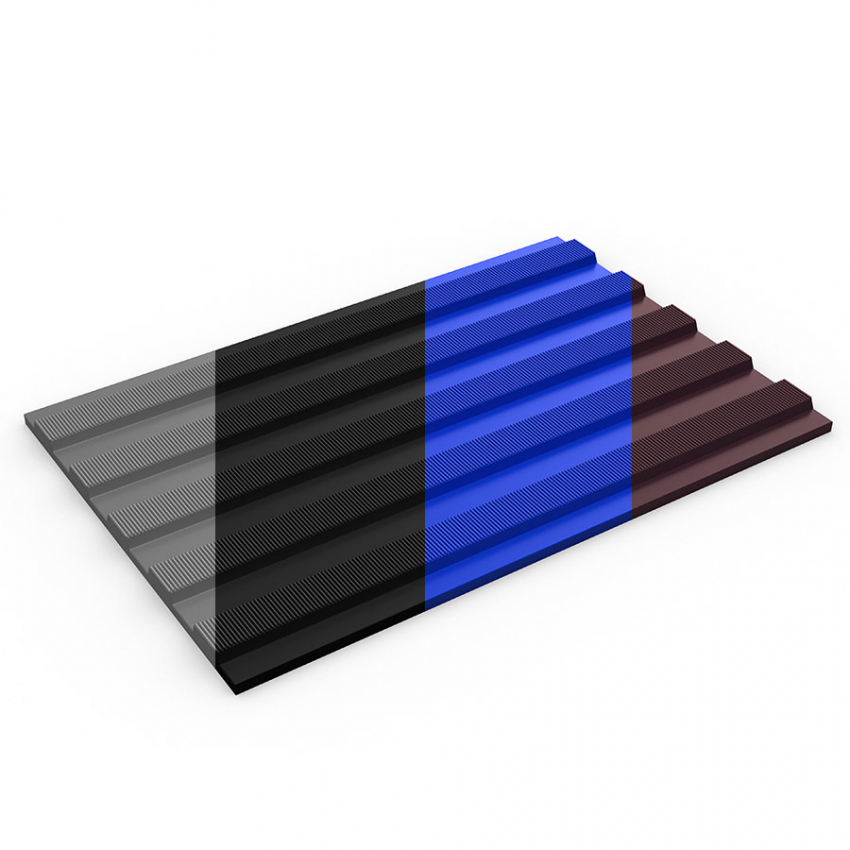

Best-seller in terms of electrical insulation coating: designed for work areas that may pose a risk of electrical discharge and where underfoot comfort is necessary. With a breakdown voltage of 27,000 V, this mat provides electrical resistance but also withstands high levels of electrical interference and offers non-slip properties ensuring good traction on the mat.

Also available with safety beveled edges upon request for a quote.

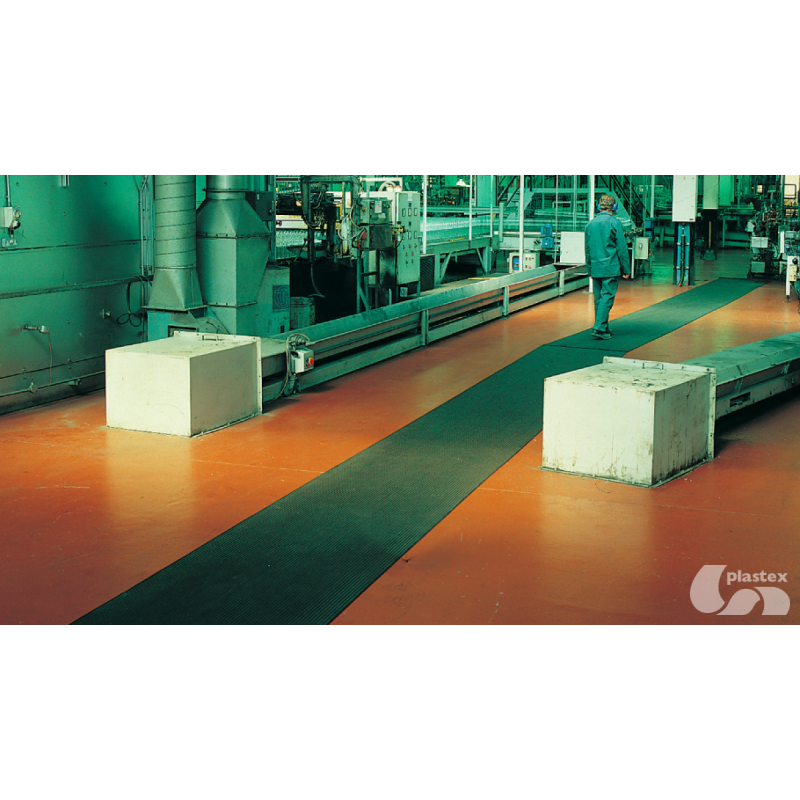

Resistant to acids, chemicals, and oils, this electrically insulating floor coating is ideal for production assembly lines, as well as commercial environments with high foot traffic.

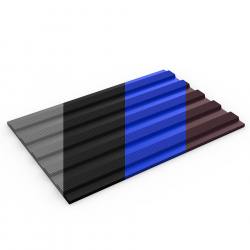

100% recyclable. It is available in black and manufactured from recycled industrial materials. The average recycled content is at least 30%, but we strive to achieve 100% recycled content wherever possible. None of the substances from the SVHC list of the REACH regulation are used in our coatings.

BS 2782: 2nd part, Method 230A

Insulation resistance > 2000M Ω

Dielectric strength = 20,000 volts

DIN 60243-1 (VDE 0303 part 21): 1999-03

Breakdown voltage: 27,050 kV eff

UL 94. Horizontal burning test. Classification 94HB

Available in rolls.

Easy to cut on-site. Excellent adhesion to the subfloor.

Lift or roll the mat to clean, no specific tools required.

| FLT |

Data sheet

| Format | Roller |

| Properties | Insulation |

| Composition | PVC (Polyvinyl chloride) |

| Thickness | 4 mm |

| Resistant to chemicals | Yes |

| Environment | Dry environments |

| Intensity of use | Intense |

| Wear index | 2/3 (Very good) |

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.