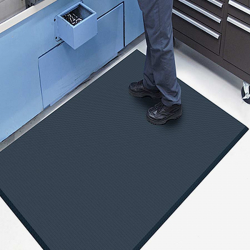

Tapis antistatique en mousse PVC

Convient aux environnements intérieurs secs

Ergonomie accrue grâce à son épaisseur. Dissipant statique combinant une surface rigide laminée sur une confortable mousse de vinyle pour une durée de vie et des propriétés antifatigue optimales. Equipé d’un point de connexion femelle et d’un câble de raccord à la terre. Surface vinyle en tôle de diamant procurant une adhérence parfaite et une facilité de mouvement. Avec revêtement antidérapant RedStop™ pour éviter aux tapis de glisser. Technologie de fabrication UniFusion™, développée pour résister aux milieux professionnels les plus durs.

Disponibles en dimensions standards

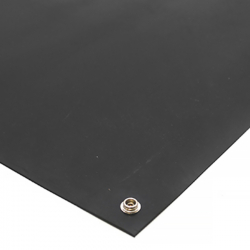

Charge électrostatique (test de marche), en accord avec les normes ISO6356 et EN1815. Conforme à la norme IEC61340-4-1 (Catégorie DIF), résistance mesurée Rg 10⁶ - 10⁹ Ω, Rp 10⁶ - 10⁹ Ω.

Sans DOP, sans DMF, sans substances appauvrissant l'ozone, sans silicone et sans métaux lourds.

APPLICATIONS RECOMMANDÉES:

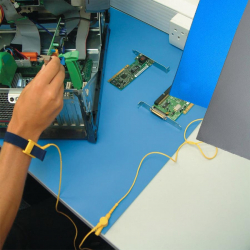

Zone sensibles à l'électricité statique.

Convient aux environnements intérieurs secs.

| 826 Diamond Stat |

Data sheet

| Format | Mat Roller |

| Design | Diamond |

| Properties | Anti-fatigue ESD / AS Fire resistant Non-slip |

| Composition | 100% recycled PVC |

| Thickness | 14 mm |

| Weight | 6.5 kg/m2 |

| Sole | Static dissipative PVC foam |

| Fire classification | Cfl-s1 |

| Resistant to chemicals | No |

| Environment | Dry environments |

| Operating temperature | 0°C to +60°C |

| Intensity of use | Very intense |

| Wear index | 3/3 (Excellent) |

| Anti-slip classification | R10 |

- musculoskeletal disorders (MSD),

- electrical shocks ,

- ensure a clean and healthy environment in the food industry, by preventing the proliferation of bacteria for example.

- Anti-fatigue mats : can be used in manufacturing industries, packaging centers, retail outlets and catering establishments.

- Antistatic mats: used in industries (welding stations).

- Agri-food mats: used in industrial kitchens, restaurants/hotels, canteens, etc.

- Wet environment: in a wet environment, the mat must not be slippery, so it must have anti-slip properties and a perforated surface to allow drainage of liquids.

- Dry environment: in a dry environment, the mat must have a granular, ergonomic bubble, striated or diamond plate surface. However, depending on the environment in which the mat is used, it must meet specific hygiene standards (kitchens, pharmaceutical industries, food processing plants, etc.).

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.