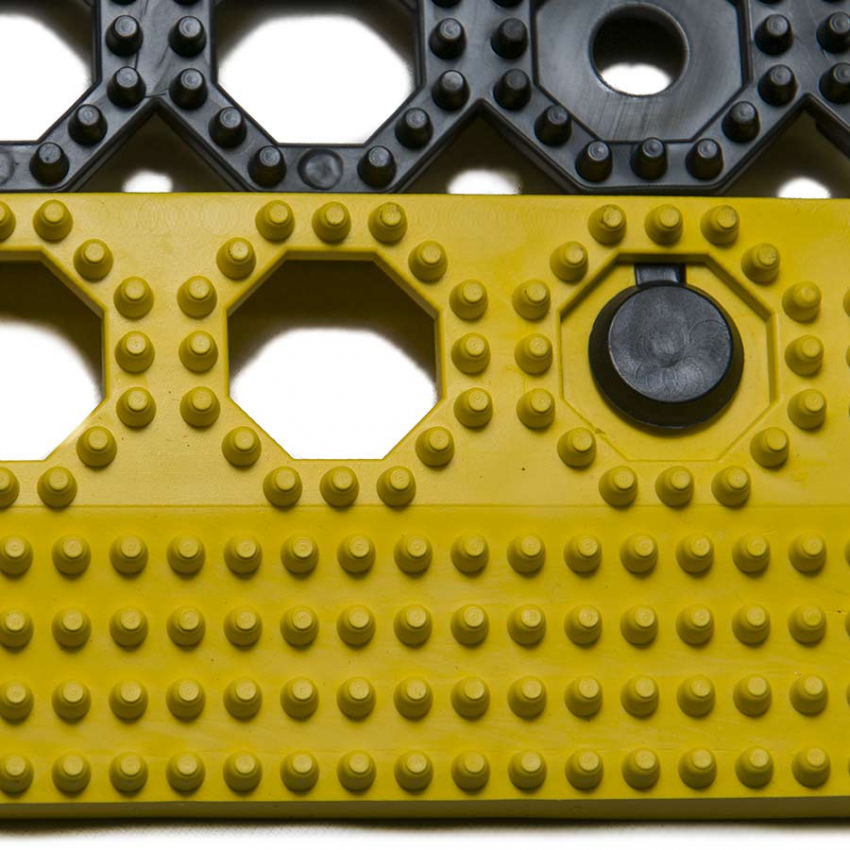

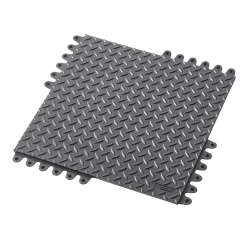

Non-slip clip-on pvc tiles

Embeddable PVC tiles with an open grid surface, designed for industrial work areas with intensive traffic where liquid spillage is likely. Industrial tile system, particularly resistant, certified anti-slip and made from 100% recycled materials.

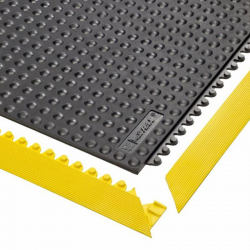

Also available with beveled safety edges on request.

The surface of these honeycomb tiles offers excellent adhesion, while the non-porous PVC resists chemicals, oils and acids. The raised surface and bevelled edges make these tiles ideal for industrial flooring.

100% recyclable and made from 100% recycled PVC.Manufactured from non-porous PVC, this grating limits the spread of bacteria and mould, ensuring quality floor hygiene.

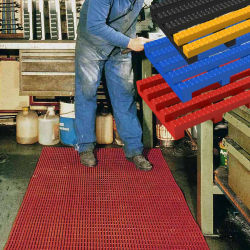

SIMPLE INSTALLATION:

Embeddable pvc slabs that can be easily interlocked with each other, attaching firmly to one another.

EASY MAINTENANCE:

Clean with a high-pressure water jet.

RECOMMENDED APPLICATION :

In industry: at workstations, assembly lines, laboratories and storage areas where liquid spills are frequent and good drainage essential. Or in marine environments (pontoons, jetties and moorings, workboats, bunker linings).

| PLK |

Data sheet

| Format | Slabs |

| Properties | Draining |

| Composition | PVC (Polyvinyl chloride) |

| Thickness | 16 mm |

| Resistant to chemicals | Yes |

| Environment | Dry environments Oily environments Wetlands |

| Operating temperature | -23°C to + 60°C. |

| Intensity of use | Intense |

| Wear index | 2/3 (Very good) |

| Anti-slip classification | R12 |

| Acoustic insulation | Excellent acoustic insulation. |

| Reversion | Thermoplastic shrinkage can result in a reduction of the coating by up to 2%. This can be amplified if the temperature is high. |

| UV light | Resistant to PVC degradation |

| Drainage capacity | V10 |

- musculoskeletal disorders (MSD),

- electrical shocks ,

- ensure a clean and healthy environment in the food industry, by preventing the proliferation of bacteria for example.

- Anti-fatigue mats : can be used in manufacturing industries, packaging centers, retail outlets and catering establishments.

- Antistatic mats: used in industries (welding stations).

- Agri-food mats: used in industrial kitchens, restaurants/hotels, canteens, etc.

- Wet environment: in a wet environment, the mat must not be slippery, so it must have anti-slip properties and a perforated surface to allow drainage of liquids.

- Dry environment: in a dry environment, the mat must have a granular, ergonomic bubble, striated or diamond plate surface. However, depending on the environment in which the mat is used, it must meet specific hygiene standards (kitchens, pharmaceutical industries, food processing plants, etc.).

- Polyester grating: 65% resin for chemical and UV resistance, 35% fiberglass for high mechanical strength. Molded in panel form, it guarantees excellent resistance to varying degrees of corrosion and chemical aggression.

- Rubber gratings: All our rubber products comply with the Reach regulations adopted to better protect human health and the environment against the risks associated with chemical substances. They are water and UV resistant, anti-slip, anti-fatigue, environmentally friendly, biodegradable and recyclable.

- Hygienic grating: Made from moisture- and UV-resistant PVC, hygienic grating prevents the spread of bacteria and keeps wet environments clean while protecting users.

- Metal grating: commonly used for technical walkways and stair treads, but also in the building industry for facade elements, fencing and railing infill.

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.

Grating is a square slab of metal, polyester, rubber or PVC, made up of several parallel slats. The slats come in a variety of sizes, species and colors, and are grooved to prevent water from stagnating and the floor from becoming slippery.

Polyester gratings: Food industry - Paper and cellulose industry - Pharmaceutical industry - Plastics industry - Fiber and textile industry - Automotive and aircraft construction - Offshore installation - Sewage treatment plant - Navy and shipbuilding - Transport - Pickling and galvanizing plant.

Rubber gratings: Can be used in a wide range of applications: building entrances, walkways, stairs, access paths, production lines, ski resorts, etc.

Hygienic gratings: swimming pools - changing rooms - saunas - hotels - kitchens - steam rooms, etc.

Metal gratings: Thermal, hydroelectric, nuclear and solar power plants - Chemical and oil industries - Automotive and steel industries - Shipbuilding - Cement works - Metal processing and construction - Railways and transport