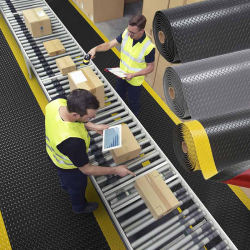

Anti-fatigue mats for production and assembly lines

All types of environments - Very intensive use

The mat is made of 100% nitrile rubber, guaranteeing resistance to the industrial oils used in manufacturing plants, production and assembly lines in the automotive and automotive subcontracting sectors. Sites with 2 or 3x8 production rhythms are particularly well suited to the use of ergonomic industrial mats.

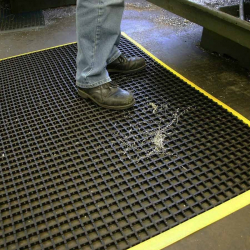

Ultra-resistant 91 cm x 91 cm rubber tiles can be easily assembled to cover large areas or to equip individual workstations, wall-to-wall or in islands.

This anti-fatigue mat is one of the products in the Cushion Ease range. This reference is suitable for most environments where oil splashes on the floor would make it slippery and dangerous. Its ergonomic comfort for operators who work on their feet for more than 4 hours a day is a real solution for reducing the onset of RSI. Production operators will be able to do their jobs at ease.

Connectable edges are to be provided according to workstation configuration.

RECOMMENDED APPLICATION :

For installation in manufacturing plants, assembly lines, CNC machines, metalworking for individual workstations and customized platforms.

| 656S Cushion ease solid nitrile |

Data sheet

| Format | Slabs |

| Surface | granular |

| Properties | Anti-fatigue Fire resistant |

| Composition | |

| Weight | |

| Borders | |

| Resistant to chemicals | Yes |

| Intensity of use | Very intense |

| Hardness | |

| Wear index | 3/3 (Excellent) |

| Anti-slip classification | R9 |

- musculoskeletal disorders (MSD),

- electrical shocks ,

- ensure a clean and healthy environment in the food industry, by preventing the proliferation of bacteria for example.

- Anti-fatigue mats : can be used in manufacturing industries, packaging centers, retail outlets and catering establishments.

- Antistatic mats: used in industries (welding stations).

- Agri-food mats: used in industrial kitchens, restaurants/hotels, canteens, etc.

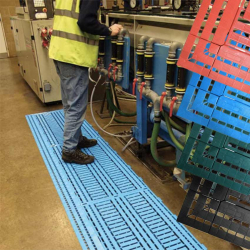

- Wet environment: in a wet environment, the mat must not be slippery, so it must have anti-slip properties and a perforated surface to allow drainage of liquids.

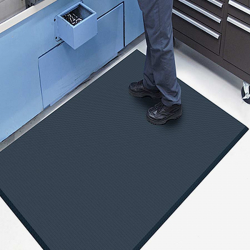

- Dry environment: in a dry environment, the mat must have a granular, ergonomic bubble, striated or diamond plate surface. However, depending on the environment in which the mat is used, it must meet specific hygiene standards (kitchens, pharmaceutical industries, food processing plants, etc.).

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

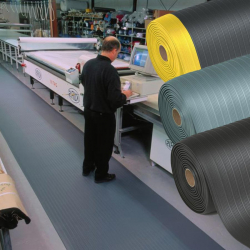

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.