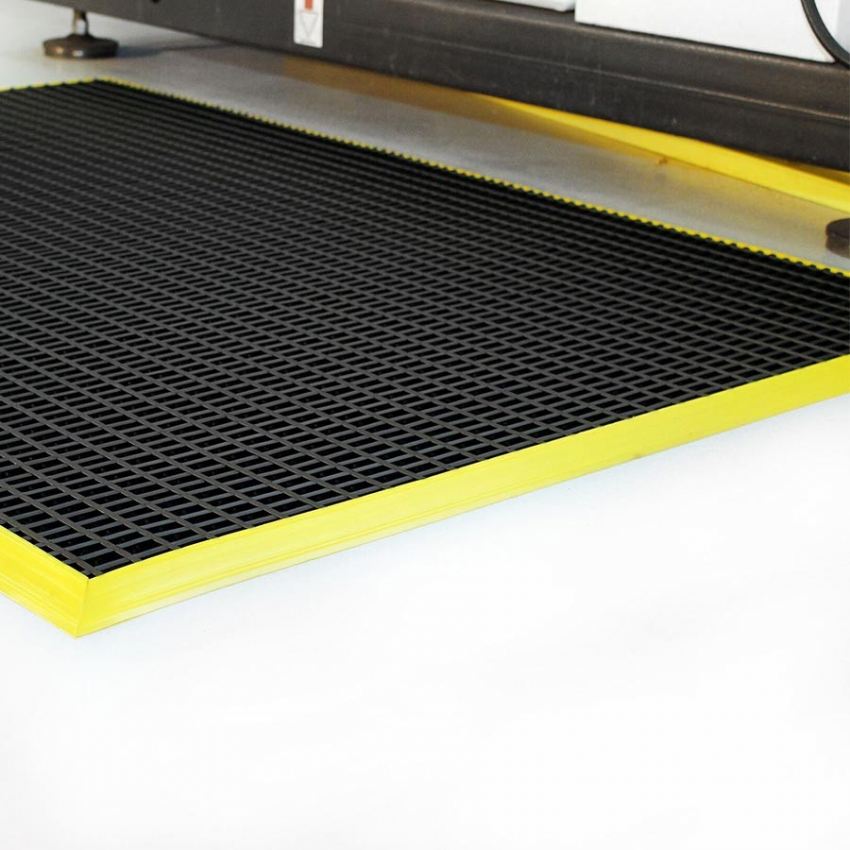

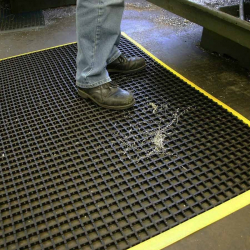

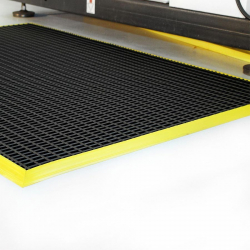

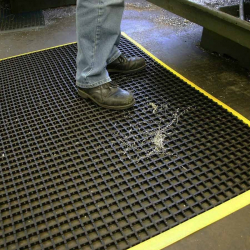

Delineating the work area, the individual anti-slip mat increases user safety thanks to its bevelled edges. The floor mat's ridges run in both directions to limit the number of accidents that can be caused by slipping. Anti-fall and fire tested, this mat is also UV and chemical/oil resistant.

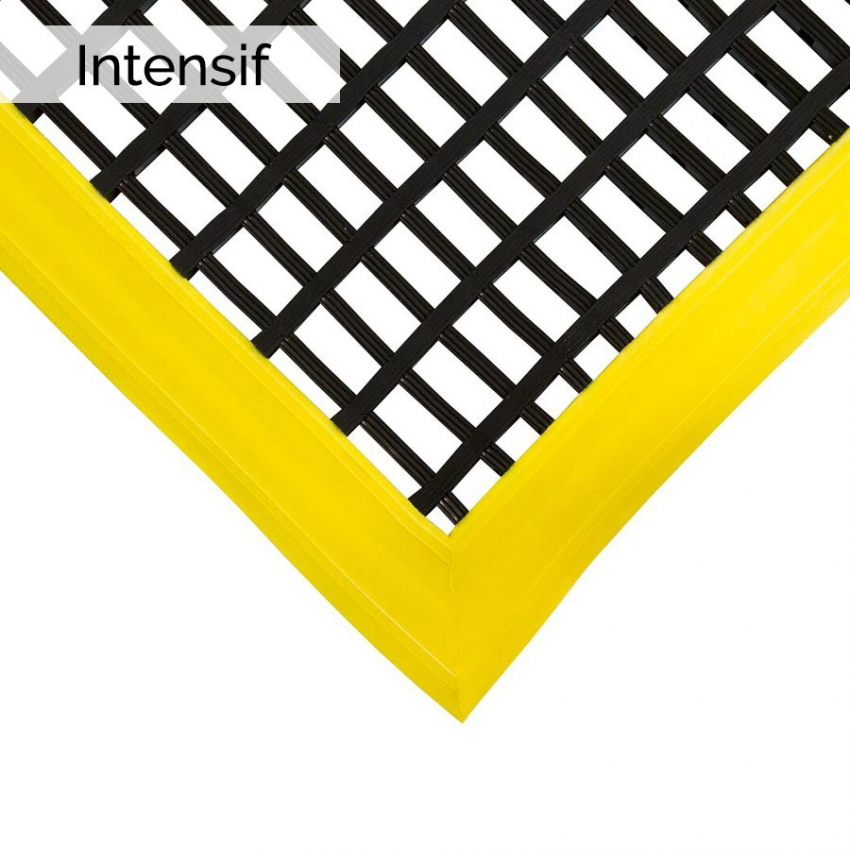

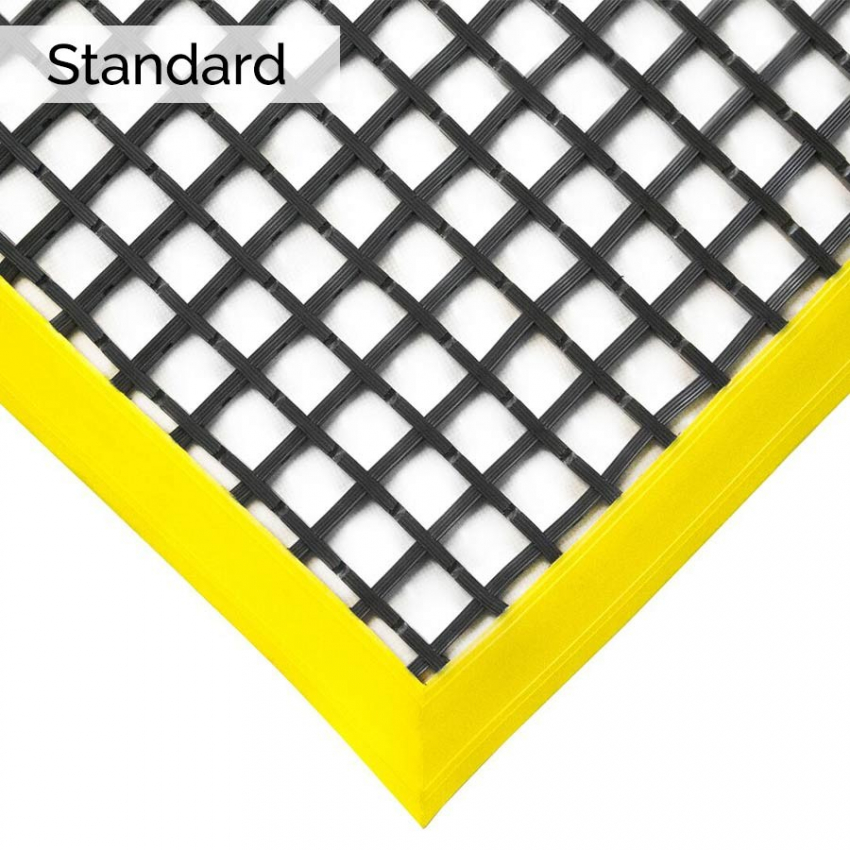

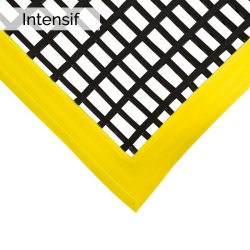

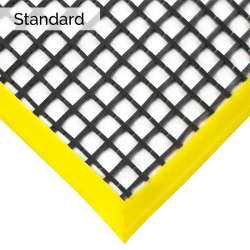

Available in standard and heavy-duty versions.

All mats are supplied with factory-fitted bevelled edges to prevent any risk of falling. Fixing cubes are available to secure the mat to the floor.

Chemical resistance: PVC is resistant to many different chemicals and alkalis, as well as general industrial chemicals. It is resistant to alcohols, aliphatic hydrocarbons, oily products, moderate acids, strong mineral acids and alkalis. When properly cleaned, PVC is resistant to greasy and oily products. PVC is not resistant to organic solvents, ketones, esters and aromatic hydrocarbons. Please contact us for further details.

Drop-proof tested to DIN 51130.

This product is suitable for wet and dry environments, indoors and outdoors. Loose installation

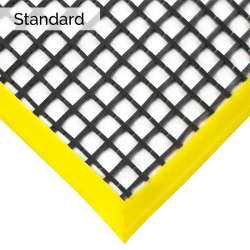

Standard version: ideal for all industrial environments, particularly in the vicinity of machine tools producing large quantities of swarf.

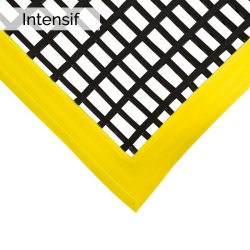

Heavy-duty version: ideal for all industrial environments, especially around machine tools in high-traffic areas and where pallet trucks and carts are used.

Manufacturing industry | Automotive / Transportation | Distribution center | Electronics | Food and beverage | Health care | Heavy industry / Metalworking | Hospitality | Light industry | Pharmaceuticals

| WD010701 |

Data sheet

| Format | Mat |

| Surface | Openwork |

| Design | Transverse grating |

| Properties | Fire resistant Non-slip |

| Composition | PVC |

| Thickness | 12 mm |

| Resistant to chemicals | Yes |

| Maintenance / Cleaning | Easy to clean with hot soapy water/pressure washer |

| Environment | Oily environments |

| Operating temperature | - 20°C to 60°C |

| Intensity of use | Very intense |

| Wear index | 3/3 (Excellent) |

| Anti-slip classification | R10 |

Industrial mats meet the needs of ergonomic workstations and employee well-being.

They prevent:

There are many uses for industrial mats:

Safety criteria: The mat must cover the entire workstation, be firmly attached to the floor, not shift or slide, and have bevelled edges to prevent falls.

Thickness and flexibility criteria: Contrary to what you might think, you shouldn't choose a very thick or very soft mat. The mat should have a certain elasticity, but still allow a comfortable standing position, without the user feeling slumped.

Environmental criteria :

Environmental hazard criteria : To establish more precise characteristics for a mat (antistatic properties or fire resistance etc...) we need to take into account the hazards present in the environment where the mat will be installed.

Where hazardous liquids are present in the working environment, the anti-slip properties and chemical resistance of industrial mats should be taken into account. The presence of openings on mats to allow the evacuation of fluids is essential.

Traffic criteria: We need to take into account the traffic that takes place on the equipment: how many workers can walk on it? How often, etc., in order to choose the most suitable mat.

Prevent the many problems associated with poor workstation ergonomics: RSI, static shock, bacterial proliferation, etc.

We offer a wide choice of industrial mats: on rolls, in standard sizes, made-to-measure or modular mats to suit all types of workstations.